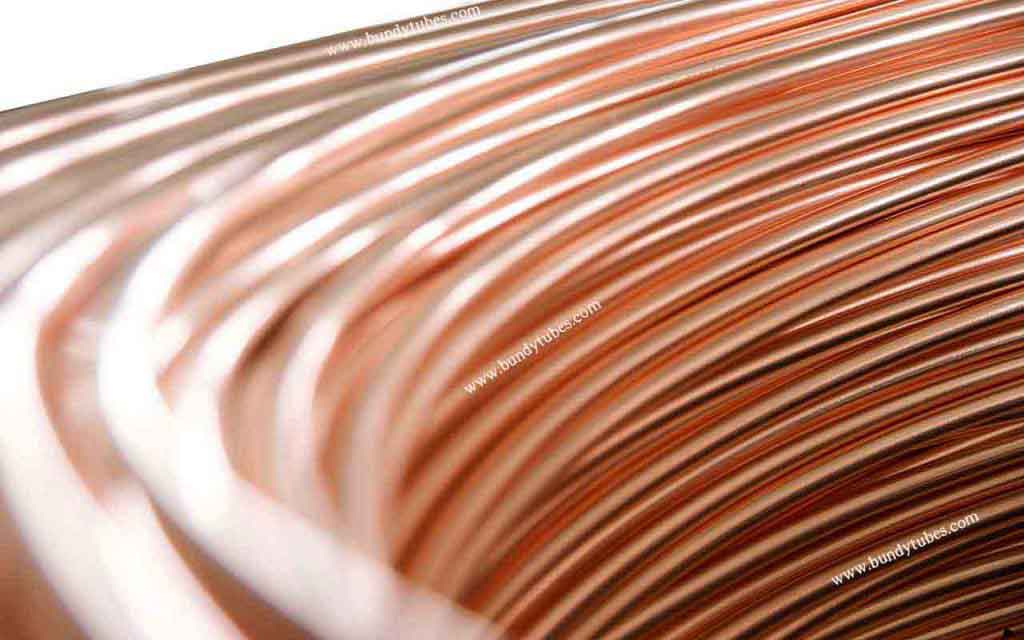

Double wall copper brazed steel tubing, also know as Bundy tube or Bundyweld tube, is the economical alternative to seamless tube. It has many of the same qualities as seamless tubing and is suitable for most high pressure applications.

- High Dimensional Accuracy

- Satisfying Mechanical Properties

- Clean Inside Surface

We are offering Bundyweld tubes of regular sizes, and at the same time capable of fabricating tubes of customized sizes.

Regular Size & Stock

Bundy tubes of the following table listed sizes are feasible to manufacture; among them, thickness of 0.7mm and 1mm are available in stock most of the time or to be produced upon being ordered.

| OD, mm | Wall Thickness, mm | ||||||

| 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | 1.3 | |

| Unit Weight (Theoretical), g/m | |||||||

| 3.18 | 33.0 | 38.2 | 42.8 | 47.0 | |||

| 4 | 43.2 | 50.3 | 57.0 | 63.1 | |||

| 4.76 | 52.5 | 61.6 | 70.1 | 78.1 | 85.7 | ||

| 5 | 55.5 | 65.1 | 74.2 | 82.9 | 91.0 | 98.6 | |

| 6 | 67.8 | 79.9 | 91.5 | 102.6 | 113.2 | 123.3 | |

| 6.35 | 72.1 | 85.1 | 97.5 | 109.5 | 121.0 | 131.9 | |

| 7 | 80.2 | 94.7 | 108.8 | 122.3 | 135.4 | 148.0 | 182.7 |

| 7.94 | 91.7 | 108.6 | 125.0 | 140.9 | 156.3 | 171.2 | 212.9 |

| 8 | 92.5 | 109.5 | 126.0 | 142.1 | 157.6 | 172.6 | 214.8 |

| 9.53 | 111.3 | 132.1 | 152.4 | 172.2 | 191.5 | 210.4 | 263.9 |

| 10 | 139.1 | 160.5 | 181.5 | 202.0 | 222.0 | 278.9 | |

| 12 | 168.7 | 185.1 | 221.0 | 246.4 | 271.3 | 343.0 | |

| 12.7 | 179.0 | 207.2 | 234.8 | 261.9 | 288.5 | 365.5 | |

| 14 | 229.6 | 260.4 | 290.8 | 320.6 | 407.2 | ||

| 15.88 | 260.7 | 295.9 | 330.7 | 365.0 | 464.9 | ||

| 16 | 264.1 | 299.9 | 335.2 | 369.9 | 471.3 | ||

Custom Sizes

We are capable of fabricating Bundy tube sizes which are not regularly used. By combining one or more processes of cold draw and annealing, Bundy tubes can be made to many other sizes to meet demands for special applications.

Click here to calculate the tube weight.

Dimensional Accuracy

| OD | Tolerance | Wall Thickness | Tolerance |

| <4.76 | ±0.05 | 0.5 | ±0.07 |

| 4.76-8 | ±0.08 | 0.5-0.7 | ±0.08 |

| 8-12.7 | ±0.10 | 0.7-1 | ±0.09 |

| >12.7 | ±0.12 | 1-1.3 | ±0.1 |

Material

The Bundyweld tubes are made from low carbon steel strips (grade BHG2) which is manufactured by Bao Steel Group. The chemical compositions are as following:

| Element | C | Si | Mn | P | S |

| Standard (max, %) | 0.06 | 0.03 | 0.3 | 0.03 | 0.03 |

Mechanical Properties

| Tensile Strength | 42000psi (290MPa) |

| Yield Strength | 26100psi (180MPa) |

| Elongation | ≥25% |

| Expansion | ≥20% |

Inside Surface Cleanliness: 0.16g/m2 , max

Burst Pressure

| OD, mm | Wall Thickness, mm | ||||||

| 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | 1.3 | |

| Burst Pressure, MPa | |||||||

| 3.18 | 119.4 | 148.8 | 180.6 | 215.1 | |||

| 4 | 91.4 | 112.9 | 135.8 | 160.0 | |||

| 4.76 | 75.1 | 92.3 | 110.3 | 129.3 | 148.2 | ||

| 5 | 71.1 | 87.3 | 104.2 | 121.9 | 140.5 | 160.0 | |

| 6 | 58.2 | 71.1 | 84.5 | 98.5 | 112.9 | 128 | |

| 6.35 | 54.7 | 66.8 | 79.3 | 92.3 | 105.7 | 119.6 | |

| 7 | 49.2 | 60.0 | 71.1 | 82.6 | 94.4 | 106.7 | 146.0 |

| 7.94 | 43.0 | 52.3 | 61.9 | 71.7 | 81.8 | 92.2 | 125.3 |

| 8 | 42.7 | 51.9 | 61.4 | 71.1 | 81.1 | 91.4 | 124.2 |

| 9.53 | 35.4 | 43.0 | 50.7 | 58.6 | 66.7 | 75.0 | 101.1 |

| 10 | 40.9 | 48.2 | 55.7 | 63.3 | 71.1 | 95.6 | |

| 12 | 33.7 | 39.6 | 45.7 | 51.9 | 58.2 | 77.8 | |

| 12.7 | 31.7 | 37.3 | 43.0 | 48.8 | 54.7 | 73.0 | |

| 14 | 33.7 | 38.8 | 44.0 | 49.2 | 65.5 | ||

| 15.88 | 29.5 | 34 | 38.5 | 43 | 57.1 | ||

| 16 | 29.3 | 33.7 | 38.1 | 42.7 | 56.6 | ||

Manufacture Standards

For Bundy tube manufacture, generally standards of China, US, Japan and other countries are very similar, and replaceable and our tubes meet all of them, except that the material compositions are slightly different among countries.

- China YB/T 4164

- US ASTM A254, SAE J527

- Japan JASO M101

- Russia GOST 11249

- India IS 8119

Tube Application

- Automotive Hydraulic Brake Lines

- Automotive Power Steering Lines

- ACR Coolant Transmission Lines

- Other Heat Exchanging Equipement

- Other Fluid Transmission

Manufacture Process

- Steel sheets electro-plated with copper on both sides

- Steel sheets cut into strips of proper widths

- Steel strips rolled in 720 degrees to form un-welded tubes

- Un-welded tubes heated over 1050 ℃ to melt the copper plating

- Copper on contacting surfaces fuses together

- Copper and steel atoms cross Infiltrate forming a thin alloy layer

- Tube cools down and tube manufacture ends

- Do the plating/coating per buyer’s requirements

Click here to watch the videos of the Bundyweld tube production.

Inspection

- Eddy Current (Non-Destructive) & Visual Inspection

- Flattening & Bending Test

- Expansion & Flaring Test

- Tension Test

- Inside Surface Cleanliness Test

- Pressure Proof Test

Click here to learn more about the inspections and tests for the Bundy tubes.